6 Oliver Pharr with ODR

For a definition of the Oliver Pharr method see [11].

This method is shown unless the software was compiled without Fortran support.

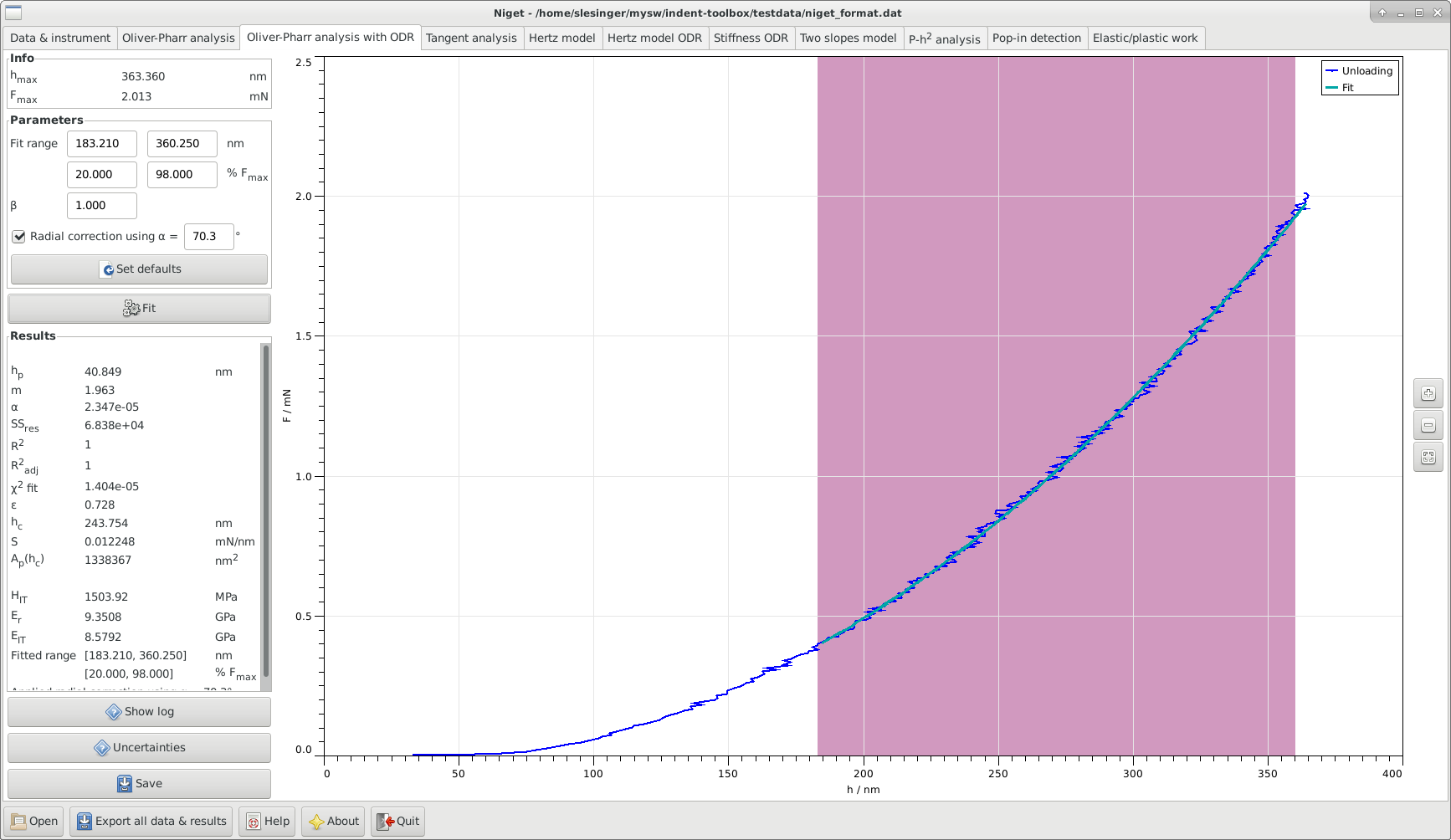

6.1 Window

The window consists of several blocks:

-

•

Info displays the maximum depth and force during the indentation

-

•

Parameters shows the selected range in nm and in % of the maximum force, the correction

, and the radial correction.

, and the radial correction.-

-

The fitting range can be selected either using the mouse or typing in the range entries. The range can be defined either in nm or in percent of the maximum force. It is often recommended to use the range 40–98 % F

for the fit, see section 6.2.

for the fit, see section 6.2. -

-

The parameter

accounts for any deviations from the axisymmetric case and is used in the calculation of the reduced modulus in equation (10).

Currently, the default value is no correction

accounts for any deviations from the axisymmetric case and is used in the calculation of the reduced modulus in equation (10).

Currently, the default value is no correction  . The value supplied by the user is saved in the settings and can be reset to its default value.

. The value supplied by the user is saved in the settings and can be reset to its default value. -

-

Optional radial correction of calculated hardness and modulus values according to ISO 14577-1:2015. The angle

denotes the cone-equivalent angle between the tip side and axis. For a Berkovich tip,

denotes the cone-equivalent angle between the tip side and axis. For a Berkovich tip,  .

. -

–

Set defaults button resets the fitting range, the beta value, and radial correction settings according to recommendations provided in ISO 14577-1.

-

-

-

•

Fit button, see section 6.2 for details of the calculation.

-

•

Results displays all results in the following order: the residual depth

, the power

, the power  of the power law function, the parameter

of the power law function, the parameter  ,

the contact depth

,

the contact depth  , the slope

, the slope  , the contact area

, the contact area  , the indentation hardness

, the indentation hardness  , the contact modulus

, the contact modulus  , the indentation modulus

, the indentation modulus  and the ranges used for the fitting procedure.

The variables are described in detail in section 6.2. If the fittings procedure failed a warning is shown.

and the ranges used for the fitting procedure.

The variables are described in detail in section 6.2. If the fittings procedure failed a warning is shown. -

•

Uncertainties show the uncertainty analysis window, see section 15.2.1.

-

•

Show log Show the report about the fitting procedure in a separate window. The reports are saved to files fit.log.op.err and fit.log.op.rpt.

-

•

Save save parameters and results to given file.

-

•

Graph display the unloading curve and the fitted curves. Stepwise zooming/unzooming can be performed by selecting a range with the mouse and pressing the Zoom/ Unzoom buttons. The graph is restored to its original size by the Restore button.

6.2 Procedure

This is a slight modification of the standard Oliver Pharr method described in section 5.2 using a better fitting procedure.

-

1.

Fit the upper part of the unloading curve with a power law function

using orthogonal least squares as implemented in the package ODRPACK95 [13]. The range should be approx. 40–98 % F

. All three parameters are fitted.

. All three parameters are fitted. -

2.

Same as steps 3–4 in 5.2.

-

3.

If the radial correction is on, the hardness and reduced modulus are found by iterating the following relations

(12)

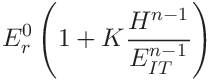

(13) where

and

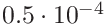

and  are the initial estimates obtained from step 4 in section 5.2. The iteration limit is set to a relative difference

are the initial estimates obtained from step 4 in section 5.2. The iteration limit is set to a relative difference  Young’s modulus is updated in each step according to (11) and

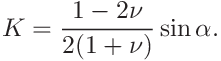

Young’s modulus is updated in each step according to (11) and  is the radial correction factor computed from Poisson’s ratio and the angle between tip sides and axis

is the radial correction factor computed from Poisson’s ratio and the angle between tip sides and axis

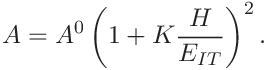

(14) The area function is corrected with the final values of hardness and modulus as

(15)